Champagne is based on three different grape varieties: two dark types, Pinot Noir and Pinot Meunier and another white variety, the Chardonnay. But how can dark grapes be used to produce white wine? The secret lies in the process of making champagne– la Méthode Traditionelle.

La Méthode Traditionelle – less acidity as the goal. All components during the process of making champagne focus on the transformation of acidic grapes into the most exclusive drink in the world. Bubbles, yeast, chaptalisation, dosage, blending and ageing – to create flavour, complexity, texture and balance.

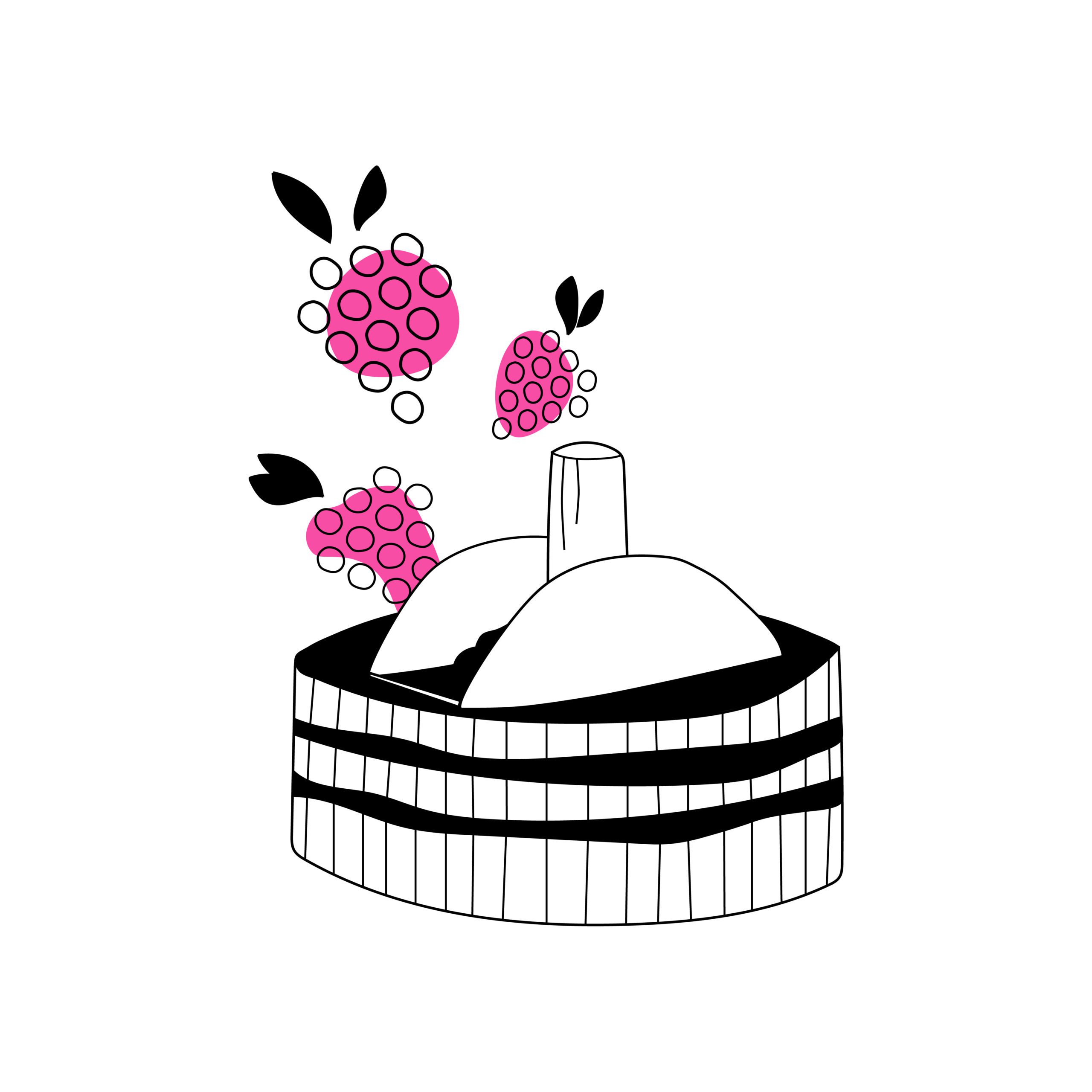

PRESSING: THE FIRST STEP OF MAKING CHAMPAGNE

Careful and selective harvesting is the secret ingredient of making champagne. Handpicking is a must to guarantee the high quality. Mechanical harvesting is not allowed in the Champagne because it is important not to destroy the skins before pressing.

The handpicked grapes from the wine yards were gently pressed in four-tonne-lots.

Only the first 2550 litres of the four tonnes were used as it is required by law. The first 2050 litres are known as the ‘coeur de la cuvée’, the heart of the cuvée, the purest and clearest juice. The tailles that represent the last 500 litres are coarser, inferior juice which flows last from the press. Its darker and more impure appearance results from the greater pressure gradually exerted in the press. Depending on the style of the champagne house, it is processed in varying levels and only rarely in the finest cuvées.

Before the first fermentation solids and impurities have to be removed from the pressed juice (known as the ‘Débourbage’).

ASSEMBLAGE – THE ART OF BLENDING

The first fermentation takes place in stainless steel tanks. Nevertheless, traditional oak barrels are used again today for fermentation. The ripeness of the grape defines the potential alcohol of the finished champagne. Many producers use ‘Chapitalisation’ prior to the fermentation process by adding sugar to increase the alcohol content. Inoculation describes the adding of cultured or wild yeast. The following aloactic fermentation softens the wine. Therefore, malic acid is converted into lactic acid.

Assemblage is defined as the art of blending when making champagne. Combining different grapes (Chadonnay, Pinot Noir and Meunier) from different vineyards ensures the quality of the Champagne although the seasons are quite erratic. The cuvée is the distinguishing feature of each champagne house and needs to be consistent over years. Non-vintage wines are deepened by adding older vintages to get more complexity and consistency. Today, warmer vintages are more common and need more freshness from older reserves.

SECOND FERMENTATION OF CHAMPAGNE MAKING

Prior to bottling a mixture of sugar and wine is added (le liqueur de tirage). The vintages are bottled and sealed with a bottle cap. Now, they can be filtered and cold stabilised.

The sugar that was added before the bottling induces the second fermentation in the process of champagne making – the “prise de mousse”. The resulting CO2 cannot escape from the bottle and creates the sparkling wine. Finer still wines and cooler cellars create bottles with smaller bubbles. A finer bead is an indicator of quality.

After several months all added yeast cells are died and the fermentation process is complete. The dead yeast cells remain in the bottle and the Champagne ages in the cellar for more years. This provides the Champagne with a yeastier character and contributes to its complexity and texture.

The minimum ageing process in champagne takes 15 months for non-vintage wines and three years for Vintages. Most of the best champagne houses exceed these minimums by maturing their non-vintage cuvées 3-4 years, vintage cuvées up to 8 years and prestige cuvées 10 years or more.

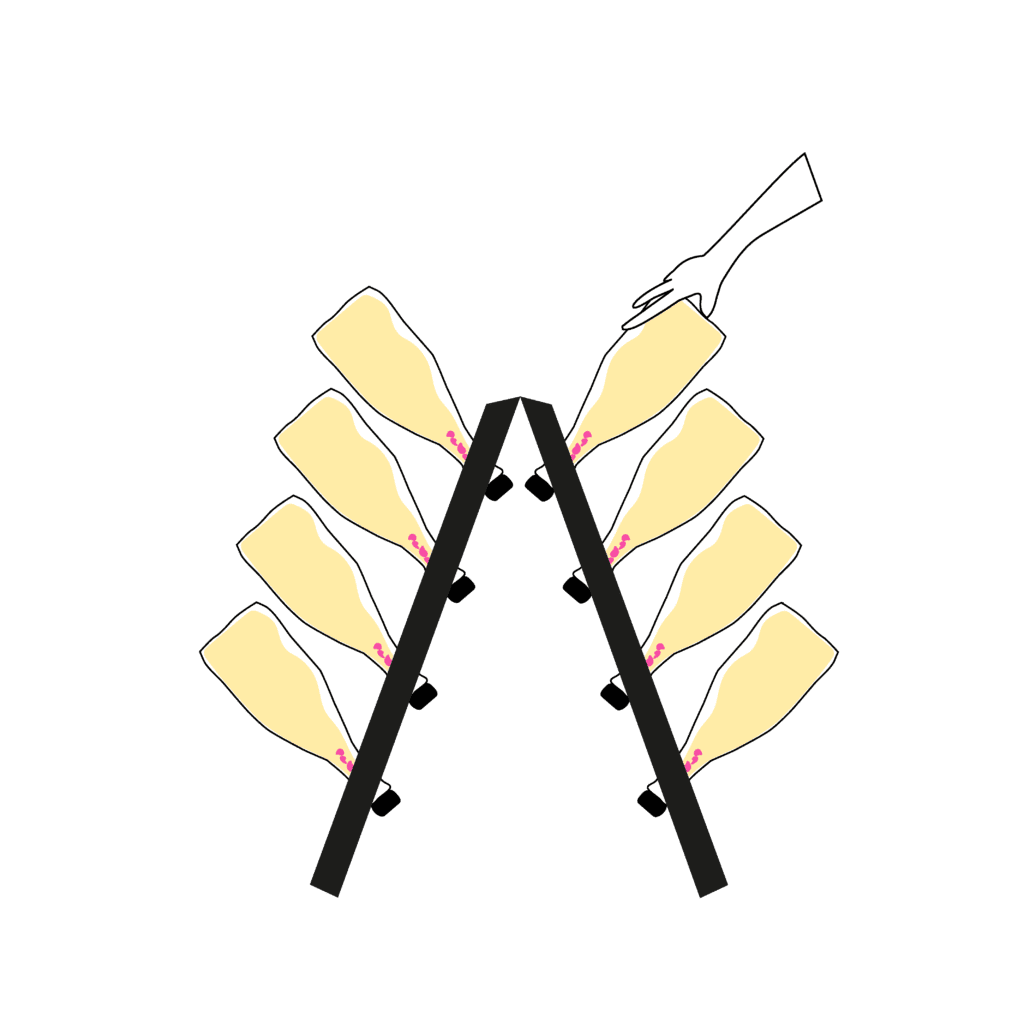

RIDDLING – TRADITIONAL BOTTLE TURNING

After the champagne is matured all dead yeast cells are removed by a process known as riddling. This special step of making champagne goes back to the 19 th century, where Antoine Müller from Veuve Cliquot, searched for a process that cleans the wine and keeps all bubbles at the same time.

During Riddling, the Champagne is placed upside down in a wooden desk with a 75-degree angle. Each bottle is given a quarter-rotation every day and is slowly tilted from horizontal to upside down. This process leads the yeast cells into the bottleneck.

Nowadays, the process is mostly done by robotics because of time savings.

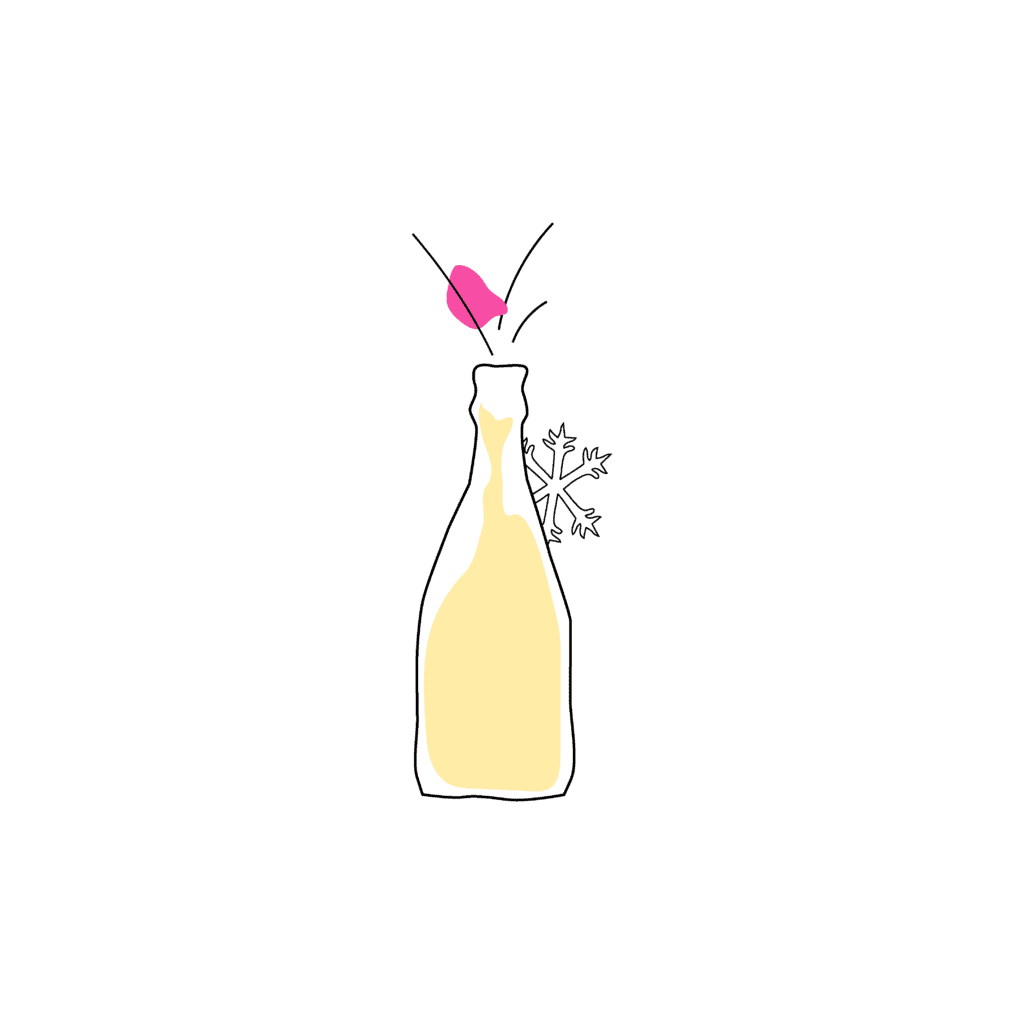

DÉGORGEMENT

After the riddling procedure, the yeast cells need to be removed from the bottleneck. Therefore, the neck of the bottle is frozen at -27 degrees, which results in the formation of a plug of frozen wine including the dead yeast cells. As a result, the bottle cap can be removed, and the frozen plug comes out.

LA DOSAGE: THE LAST STEP OF MAKING CHAMPAGNE

The last step of making champagne is known as ‘Dosage’. During the process of disgorgement some wine is lost. The following dosage defines the topping up with sweetened wine (known as liqueur d’expédition). After all, the bottle is shaken, and a new cork is inserted. The dosage decides whether a Champagne will be Brut Nature, Extra Brut, Brut or Zero Dosage depending on the added amount of sugar.

ET VOILÀ, THE CHAMPAGNE IS READY

Besides choosing the right champagne, it is also important to open the champagne bottle correctly. If you want to learn more about the right technique, check out our article on “How to open a champagne”.

OUR CHAMPAGNE-RECOMMENDATIONS

-

LACOURTE-GODBILLON ROSÉ PREMIER CRU BRUTFrom: €59,00Includes 19% VAT(€78,67 / 1 L)plus shipping

LACOURTE-GODBILLON ROSÉ PREMIER CRU BRUTFrom: €59,00Includes 19% VAT(€78,67 / 1 L)plus shipping -

Tarlant Rosé Brut€45,50Includes 19% VAT(€60,67 / 1 L)plus shipping

Tarlant Rosé Brut€45,50Includes 19% VAT(€60,67 / 1 L)plus shipping -

De Sousa Brut TraditionFrom: €46,50Includes 19% VAT(€62,00 / 1 L)plus shipping

De Sousa Brut TraditionFrom: €46,50Includes 19% VAT(€62,00 / 1 L)plus shipping